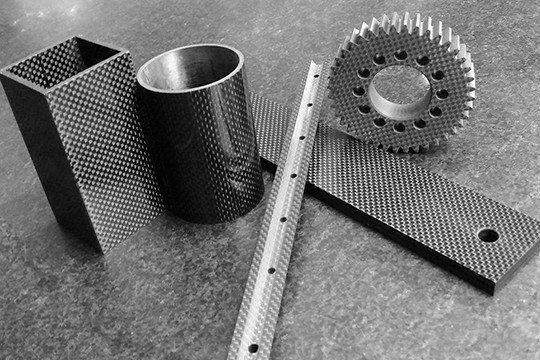

Carbon Fiber Reinforced Plastic Market Size and Trends 2025-2033

Market Overview:

The Carbon Fiber Reinforced Plastic (CFRP) Market is experiencing significant expansion, driven by Rising Demand for Lightweight Automotive Components, Growing Aerospace Industry Applications and Increasing Product Utilization in Construction Materials. According to IMARC Group's latest research publication, "Carbon Fiber Reinforced Plastic Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025–2033", The global carbon fiber reinforced plastic (CFRP) market size reached USD 21.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 35.9 Billion by 2033, exhibiting a growth rate (CAGR) of 5.64% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/carbon-fiber-reinforced-plastic-market/requestsample

Our Report Includes:

- Market Dynamics

- Market Trends and Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Carbon Fiber Reinforced Plastic Industry:

- Rising Demand for Lightweight Automotive Components

The continuous growth in automotive industry demand for lightweight components is driving significant adoption of carbon fiber reinforced plastic materials. CFRPs offer superior strength-to-weight ratios compared to traditionally used materials such as aluminum and steel, enabling manufacturers to produce environment-friendly and lightweight automotive components with improved fuel economy and higher efficiencies. The automotive sector's shift toward electric vehicles is further accelerating CFRP demand, as weight reduction directly impacts battery efficiency and vehicle range. This trend is particularly pronounced in premium and performance vehicle segments where weight savings translate to enhanced performance and reduced emissions.

- Growing Aerospace Industry Applications

The aerospace industry represents the largest application segment for CFRP materials, driven by stringent requirements for lightweight, high-strength materials that can withstand extreme conditions. Aircraft manufacturers are increasingly adopting carbon fiber composites for primary and secondary structures to reduce aircraft weight, improve fuel efficiency, and enhance performance characteristics. The growing commercial aviation sector, expanding defense budgets, and increasing demand for next-generation aircraft are driving substantial growth in CFRP consumption. Space exploration initiatives and satellite manufacturing also contribute to aerospace demand for advanced composite materials.

- Increasing Product Utilization in Construction Materials

CFRP materials are finding extensive applications in construction and civil engineering projects due to their durability, resistance against electromagnetic interference, and superior structural properties. Columns, piers, pylons, and reinforcing structures are increasingly manufactured using CFRP owing to their long-term durability and maintenance advantages over traditional materials. Infrastructure modernization projects, earthquake-resistant construction requirements, and the need for lightweight structural solutions in high-rise buildings are driving construction sector adoption of carbon fiber composites.

Key Trends in the Carbon Fiber Reinforced Plastic Market

- Advancement in Manufacturing Process Technologies

The market is witnessing significant innovations in manufacturing processes including automated fiber placement, resin transfer molding, and advanced compression techniques that improve production efficiency and reduce costs. These technological advancements enable mass production of CFRP components while maintaining quality and performance standards. Automated manufacturing processes reduce labor costs and production time, making CFRP more cost-competitive with traditional materials in high-volume applications.

- Development of Recyclable and Sustainable CFRP Solutions

Environmental concerns are driving development of recyclable carbon fiber composites and sustainable manufacturing processes. Manufacturers are investing in research for bio-based resins, recyclable fiber systems, and end-of-life recycling technologies to address environmental impact concerns. This trend aligns with automotive and aerospace industry sustainability goals and regulatory requirements for recyclable materials.

- Expansion in Wind Energy Applications

The renewable energy sector, particularly wind energy, is becoming a significant growth driver for CFRP materials used in wind turbine blade manufacturing. Carbon fiber composites enable production of longer, more efficient turbine blades that can capture more wind energy while maintaining structural integrity. The global expansion of offshore wind farms requires advanced composite materials that can withstand harsh marine environments, driving specialized CFRP demand.

Leading Companies Operating in the Global Carbon Fiber Reinforced Plastic Industry:

- Cytec Industries Inc.

- DowAksa Advanced Composites Holdings B.V.

- Formosa Plastics Corporation

- Hexcel Corporation

- Mitsubishi Chemical Holdings

- SGL Carbon SE

- Teijin Limited

- Toray Industries, Inc.

Carbon Fiber Reinforced Plastic Market Report Segmentation:

Breakup by Raw Materials:

- Polyacrylonitrile

- Pitch-Based

- Rayon-Based

Polyacrylonitrile currently holds the majority of the total market share due to its superior mechanical properties and cost-effectiveness in production.

Breakup by Type:

- Thermoset

- Epoxy Resin

- Polyester Resin

- Vinyl Resin

- Thermoplastic

- Polyurethane

- Polyether Ether Ketone

- Polyethersulfone

Thermoset (epoxy resin) exhibits a clear dominance in the market due to superior bonding properties and wide application compatibility.

Breakup by Manufacturing Process:

- Layup

- Pultrusion and Filament Winding

- Resin Transfer

- Injection and Compression Moulding

- Others

Layup currently accounts for the largest market share due to its versatility and suitability for complex geometries and prototype development.

Breakup by Application:

- Aerospace & Defense

- Automotive

- Wind Energy

- Civil Engineering

- Sporting Goods

- Electrical and Electronics

- Marine Applications

- Others

Aerospace & defense exhibits a clear dominance in the market driven by stringent performance requirements and high-value applications.

Breakup by Region:

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- North America (United States, Canada)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific (China) currently dominates the global market due to large-scale manufacturing capabilities and growing automotive and aerospace industries.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1–201971–6302