MANAGEMENT PROCESS FOR OBTAINING PLASTIC FIBERS THROUGH THERMAL TREATMENT OF MUNICIPAL SOLID WASTE FOR THE MANUFACTURE OF CARBON FIBERS

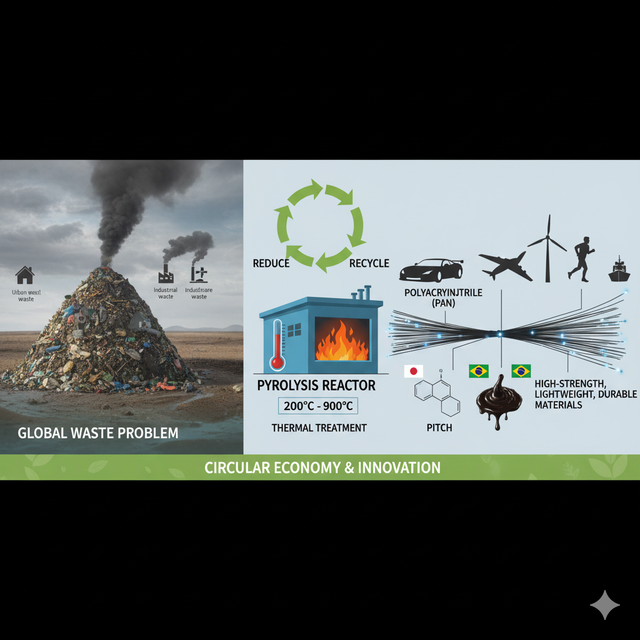

The disposal of waste is a global problem in relation to the damage and pollution caused to the environment, and if it is disposed of without any treatment, it can affect the soil, water, and air, either in isolation or in combination. Waste can be classified, according to Bill No. 1991/07, by origin, that is, urban, industrial, healthcare services, etc., and also by purpose, as reverse solid waste or rejects.

Currently, the automotive, aeronautical, civil construction, sports equipment, naval, and other industries are looking for a material that is highly resistant, very light, and very durable. Carbon fibers are essential materials for the energy sector and the aforementioned industries. The two precursors of these fibers are polyacrylonitrile (PAN), a market dominated by Japan, and pitch, which has been highly developed by the Brazilian Army Technological Center. The manufacture of carbon fibers is generally carried out by means of controlled pyrolysis of plastic fibers.

The treatment of solid waste consists of using appropriate technologies that aim to neutralize the disadvantages of the existence of waste or transform it into energy generation or a factor for the generation of secondary raw material. These technologies include reduction, reuse, recycling, treatment of solid waste, and environmentally sound final disposal of rejects. Among the thermal treatments of solid waste, one of its processes is pyrolysis, whose temperature varies from 200° to 900ºC, and minimizes the emissions of pollutants formed in an oxidizing atmosphere, such as dioxins and furans (KAMINSKY and SINN, 1996). The use of pyrolysis is employed in the reprocessing of plastics and tires to obtain fuel oils and gases and in the manufacturing of carbon fibers.