7 Critical Questions to Ask Before Purchasing an Electrical Safety Analyzer

Purchasing an electrical safety analyzer is a significant investment in quality, compliance, and most importantly, safety. Whether you're a biomedical equipment technician (BMET) in a hospital, a service manager in an independent workshop, or an industrial electrician, the tool you choose becomes the bedrock of your testing protocol. But with a market full of options, from basic manual testers to sophisticated intelligent analyzers, how do you ensure you're making the right choice?.jpg)

A modern intelligent electrical safety analyzer is more than just a "pass/fail" machine; it's a data hub, a compliance officer, and a predictive maintenance partner all in one. Asking the right questions upfront will not only guarantee you get the features you need but will also ensure your investment remains valuable for years to come.

Here are the seven critical questions you must ask before making your purchase.

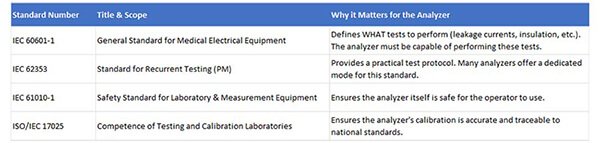

1. Does It Support the Current and Anticipated Safety Standards?

This is the most fundamental question. An analyzer that can’t perform tests to the required standards is useless.

- What to Look For: Ensure the analyzer is designed to test to the latest versions of key standards relevant to your field. For medical equipment, this is primarily IEC 60601-1. For laboratory, IT, and general equipment, IEC 62368-1 is crucial. Also, check for other common standards like ANSI/AAMI ES60601-1, UL 61010-1, or NFPA 99.

- The Intelligent Advantage: A basic tester might perform the tests, but an intelligent analyzer often has pre-programmed test routines for these standards built-in. This eliminates guesswork and ensures the tests are performed with the correct parameters, voltages, limits, and pass/fail criteria every single time, drastically reducing human error.

- Future-Proofing: Standards evolve. Ask if the manufacturer provides software updates to add new standards or revise existing test limits. This is a key feature that protects your investment against regulatory changes.

2. How Does It Simplify Data Management and Reporting?

In today’s world, a paper logbook is no longer sufficient. Regulatory bodies and auditing agencies demand digital, tamper-proof, and easily accessible records.

- What to Look For: Inquire about data storage, export options, and reporting capabilities.

- The Intelligent Advantage: This is where intelligent analyzers truly shine. They automatically generate detailed, professional PDF reports for every test, complete with date/time stamps, device identifiers, measured values, and pass/fail status. Look for features like:

- Internal Memory: Storage for thousands of test results.

- USB Export: Easy saving of data to a USB drive for transfer to a PC.

- PC Software: Companion software for managing a database of assets, tracking history, analyzing trends, and generating batch reports for audits.

- The Bottom Line: Robust data management turns a compliance burden into a simple, automated process, saving you countless hours during annual audits.

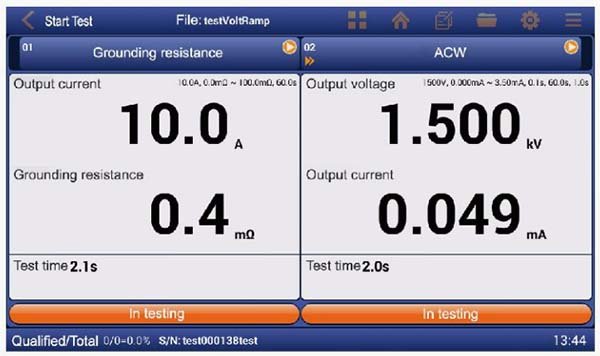

3. Is the Interface Intuitive and the Workflow Efficient?

A complex, confusing interface leads to mistakes, frustration, and slower testing times. The tool should work for you, not the other way around.

- What to Look For: A clear, graphical display (ideally color touchscreen), logically organized menus, and the ability to create and save custom test sequences.

- The Intelligent Advantage: Instead of manually configuring five different tests for a device, an intelligent analyzer allows you to create a "one-button test sequence." With a single press, it can automatically run insulation resistance, earth bond, leakage currents, and functional checks, then save the full report to the correct asset ID. This improves workflow efficiency by over 50%, reduces repetitive strain, and ensures consistency across different technicians.

4. What is the Total Cost of Ownership (TCO)?

The purchase price is only part of the equation. The long-term costs of maintaining the analyzer are just as important.

- What to Look For: Ask about the calibration cycle (typically annual), the cost of calibration, and the process. Is it a simple, self-service adjustment, or does it require shipping the unit to a certified lab? How long does downtime for calibration typically last?

- The Intelligent Advantage: Many high-end intelligent analyzers feature on-screen calibration guidance and come with calibration accessories, allowing trained technicians to perform in-house calibrations quickly and affordably. This minimizes downtime and reduces long-term costs. Also, consider the warranty length and the manufacturer’s reputation for reliability and repair support.

5. How Does It Enhance Technician Safety?

Electrical safety testing involves working with high voltages. The primary goal is to keep the technician safe during the process.

- What to Look For: Safety features like current limiters on hipot tests, secure test lead connections, and clear warnings and interlocks.

- The Intelligent Advantage: Intelligent analyzers build on this with features like Arc Detection, which can instantly shut down a test if it detects a breakdown (arc) that is too sudden or violent, protecting both the device under test and the analyzer. Furthermore, their automated sequences ensure the technician is following a safe, predefined process, minimizing hands-on interaction with the device once the test begins.

6. Can It Grow and Adapt with My Future Needs?

Your needs today might not be your needs in five years. Will your analyzer become obsolete?

- What to Look For: Modularity and upgradeability. Can you add new test modules or accessories later?

- The Intelligent Advantage: The most future-proof aspect of an intelligent analyzer is its software. As mentioned, the ability to add new test standards via updates is critical. Furthermore, consider if the platform can integrate with other systems. Could its data be exported to an Enterprise Asset Management (EAM) or Computerized Maintenance Management System (CMMS) like Maximo or SAP in the future? This scalability is a hallmark of a wise investment.

7. What Kind of Support and Training Does the Manufacturer Offer?

A sophisticated tool is only as good as your ability to use it effectively.

- What to Look For: Comprehensive support includes detailed user manuals, video tutorials, application notes, and responsive technical support by phone or email.

- The Intelligent Advantage: Leading manufacturers offer dedicated application engineers and even on-site or virtual training sessions to get your entire team up to speed quickly. This ensures you are leveraging the full power of your analyzer from day one, rather than just using a fraction of its capabilities.

The Future is Connected and Intelligent

Looking beyond today's needs, the next wave of electrical safety analyzers is already taking shape through the Internet of Things (IoT) and advanced data analytics. The "intelligent" analyzer of tomorrow will be even more integrated:

- Seamless Cloud Connectivity: Test results will automatically sync to a secure cloud platform the moment a test is completed, accessible from anywhere for managers and auditors.

- Predictive Analytics (AI): The system won't just record data; it will analyze it. By tracking historical trends across a fleet of devices, it could automatically flag a device that, while still passing, is showing a steady increase in earth bond resistance or a decline in insulation integrity. This allows for truly predictive maintenance, fixing issues before they cause equipment failure or a safety hazard.

- Augmented Reality (AR) Guidance: Technicians could use AR glasses to see test instructions and results overlaid on the actual equipment they are testing, streamlining complex procedures.

Conclusion

Purchasing an electrical safety analyzer is a decision that impacts your operational efficiency, regulatory compliance, and fundamental safety protocol. By moving beyond the basic specs and asking these seven critical questions, you shift the conversation from price to value.

An intelligent electrical safety analyzer, with its automated workflows, impeccable data management, and future-proof design, isn't just a tool—it's a strategic partner. It empowers your technicians, protects your organization, and builds an unassailable culture of safety and quality. Invest the time in asking these questions now, and you'll reap the benefits of a smarter, safer, and more efficient operation for years to come.