Electric Vehicle Polymers Market — A Rapid Ascent Fueled by EV Adoption

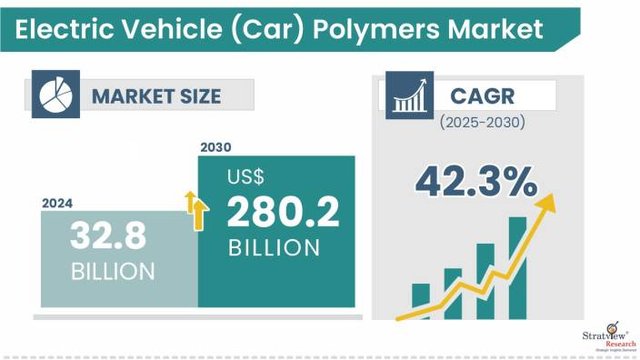

The Electric Vehicle (Car) Polymers Market is growing at a breakneck pace, underpinned by the surging demand for lighter, more efficient, and safer electric vehicles (EVs). According to a Stratview Research report, the Electric Vehicle (Car) Polymers Market was valued at USD 32.8 billion in 2024 and is projected to grow at a Compound Annual Growth Rate (CAGR) of ~42.3% during 2025-2030. Polymers here include engineering plastics, elastomers, and other high-performance materials used in interiors, exteriors, powertrain systems, etc.

Request the Sample Report Here:

Drivers

Several inter-locking factors are pushing this market ahead:

• Vehicle lightweighting and range extension: Battery packs are heavy; to improve driving range without constantly increasing battery size (which adds cost), automakers are replacing heavier metal parts with polymers and composites. Reducing overall vehicle weight improves EV efficiency.

• EV adoption & regulatory pressure: Governments around the world are mandating lower emissions, higher fuel/electric efficiency, often giving incentives for EVs. This increases production volumes of EVs, thus boosting demand for polymers suited to EV needs (heat resistance, electrical insulation, vibration/durability).

• Performance & safety requirements: Polymers are used not just for styling or weight-saving, but also for insulating battery enclosures, thermal management, sealing out moisture or chemicals, vibration damping, and crash safety components. These functional requirements demand advanced polymer formulations.

• Growing component diversity: A wider range of parts in EVs now use polymers — exteriors (panels, trims), powertrain parts (housing, covers), interiors (dash, seats, trim), etc. As EV architectures evolve (modular battery systems, integrated electric drive units), more polymer usage is embedded in multiple components.

Trends

Here are some trends to watch in this market:

• Engineering plastics and elastomers are key types: The market segmentation includes engineering plastics (ABS, PA, PC etc.) and elastomers. Elastomers are important for sealing, vibration damping, cable insulation etc., while engineering plastics are used for structural, exterior, and interior components.

• Component segmentation: Interiors, exteriors & powertrain share growth: Interior components are important, but exteriors and powertrain/housing see strong polymer usage as well. Exterior parts are seeing polymers used more for lightweight panels, cladding etc.

• Regional dominance: Asia-Pacific leads: Asia-Pacific is expected to be a major region for growth. Countries such as China, Japan, South Korea are driving demand through large EV production, strong policy support, and cost advantages in manufacturing.

• Material & innovation pushes: Requirements of heat resistance, durability, flame retardancy, electrical insulation, and lighter weight are pushing polymer development. Also, plastics that can endure under-hood/high-temp conditions, battery safety, and long life are becoming more used.

Conclusion

The Electric Vehicle (Car) Polymers Market is on a very fast growth trajectory: USD 32.8B in 2024, rising at ~42.3% CAGR through 2025-2030. For polymer manufacturers, material scientists, EV OEMs, and suppliers, the opportunity is large. Key success will come from: developing high-performance polymers that satisfy safety, durability, thermal, and electrical demands; supplying cost-effective materials; and securing strong presence in Asia-Pacific markets. As EV adoption grows, polymers will play an increasingly central role in delivering better performance, lighter weight, and increased safety.