Heat Exchangers Market: Essential Components for Efficient Energy Transfer

Heat exchangers are critical components used across various industries to transfer heat between two or more fluids without mixing them. These systems are designed to improve energy efficiency, reduce costs, and optimize processes in industries ranging from oil and gas to HVAC (heating, ventilation, and air conditioning). Heat exchangers are crucial in applications where temperature regulation is key, such as in power generation, automotive cooling systems, and chemical processing.

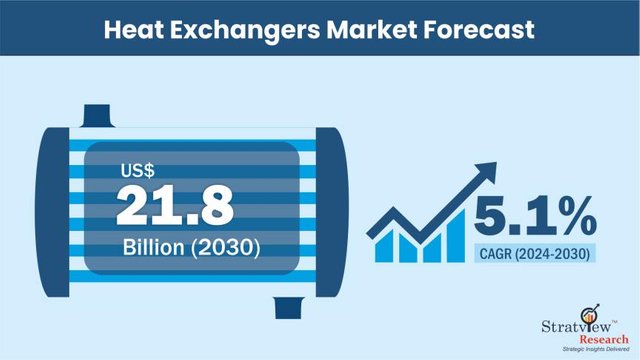

According to Stratview Research, the Heat Exchangers Market is expected to grow at a CAGR of 5.1% from 2024 to 2030, reaching a market value of USD 21.8 billion by 2030. This growth is driven by the increasing demand for energy-efficient systems, rising industrialization, and the growing focus on sustainability.

Download the sample report here, to uncover in-depth insights:

https://stratviewresearch.com/Request-Sample/2931/heat-exchangers-market.html#form

A heat exchanger is a device that facilitates the transfer of thermal energy between two or more fluids at different temperatures. These fluids, which can be gases, liquids, or both, exchange heat without coming into direct contact with each other. The most common types of heat exchangers include:

1. Shell and Tube Heat Exchangers: Often used in chemical plants, these consist of a series of tubes, one set carrying the hot fluid and the other carrying the cold fluid.

2. Plate Heat Exchangers: Made up of multiple metal plates arranged in a stack, plate heat exchangers are compact and efficient for heating or cooling fluids in industries like food processing and pharmaceuticals.

3. Air Cooled Heat Exchangers: These are primarily used in industries that need cooling without access to water, such as oil refineries and power plants.

Market Drivers for Heat Exchangers

1. Increased Energy Efficiency Demand: Industries across the board are striving to reduce energy consumption and optimize operational costs. Heat exchangers, by efficiently transferring heat and improving thermal management, help industries meet these demands and lower energy costs.

2. Industrial Expansion and Technological Advancements: As industrial processes become more complex and energy-intensive, the need for advanced heat exchangers to handle higher pressures and temperatures is growing. Innovations in heat exchanger materials and designs are also contributing to improved performance and longer operational lifespans.

3. Sustainability and Regulatory Pressures: With increasing regulatory pressure to reduce environmental impacts, industries are adopting energy-efficient solutions such as heat exchangers to comply with environmental standards and sustainability goals. This is particularly important in energy-intensive sectors like power generation and petrochemicals.

Challenges in the Heat Exchangers Market

1. High Initial Costs: While heat exchangers offer significant operational savings, the initial investment in advanced models, particularly for high-performance industries, can be high. This could be a barrier for small and medium-sized enterprises (SMEs) looking to adopt these technologies.

2. Maintenance and Durability: Over time, heat exchangers can experience wear due to corrosion, fouling, and other issues, leading to reduced efficiency and the need for frequent maintenance. This is a significant challenge, especially in industries that operate in harsh environments.

Conclusion

The Heat Exchangers Market is set to continue expanding, driven by the need for energy-efficient solutions in industries ranging from power generation to HVAC. As technological advancements improve their efficiency and sustainability, heat exchangers will remain a crucial component in modern industrial systems.