The Diary Game||Date:29-03-2025||The first day of annual electrical maintenance work during the Eid holiday.

Today, I will write my diary game dated 29-03-2025. I will share with you the parts of my daily work by writing a diary. I hope everyone will like my diary writing.

During the annual electrical maintenance work

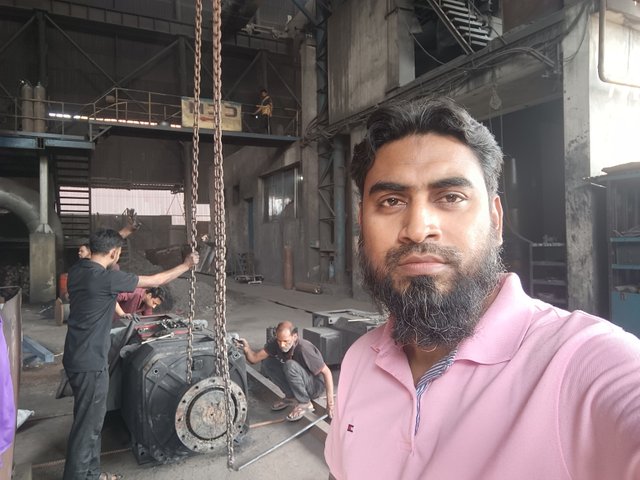

Today, I wake up at 4.00 am every day and eat to break my fast. Then I pray Fajr and sleep for some time. I woke up at 7.00 am, took a shower, and prepared to go to the office. I reach the office at 8.00 am and start work. From today, I will start the annual electrical maintenance work in the office. I am an electrical engineer. Today is the first day of six days of yearly maintenance work with my electrical team. I will schedule the maintenance of electrical appliances in six days. The production unit in our office will be closed for 6 days for Eid. Every year, I do maintenance work during the Eid holidays. My Eid vacation is closed for now. Today, I first started maintenance of an induction motor of 950 KW. It is the biggest motor in our production unit. We are working on seven electrical team maintenance.

950 KW large induction motor maintenance started

After opening the motor, I found a lot of dirt inside. We have some rules for the opening and maintenance of such big motors. Experience is required for such large motor maintenance. I have been doing this type of electrical work for about ten years. It takes us about three hours to open the motor. Then, we blow out the dirt inside the motor with air through the compressor. Open the cover on both sides of the motor until noon and take out the rotor from inside. It will take three days to maintain our motor. Maintenance of the motor is done in a few steps.

Then, I went to the mosque at noon to pray for Zohar. After praying, we started DC motor maintenance. Our schedule has eight DC motors to maintain. We started four DC motor maintenance in the first step. DC motors are in the 500, 400, and 250 kW range. These DC motors are made in India and are very expensive. We usually see small DC motors. But these DC motors are powered by inverters. These motors produce rods.

500 and 400 KW DC Motor Maintenance Time

Two parts of DC motor. One is the field coil, and the other is the rotor. The rotor field is inside the coil. We separate the rotor from the field coil using various methods. Then we clean the dirt inside the motor by air with an air compressor machine. We use a varnish called EPINITO to clean the DC motor till evening. Then, we dry the varnish on the inside of the motor using a 200-watt light.

In the evening, I come to the office and have an Iftar. I am very tired due to fasting. After the Maghrib prayer, I leave the office and go home. I come home and take some rest. Then, I write a diary blog and submit it. Then, at 11:00 p.m., I eat and sleep.

This is my Twitter share link :

https://twitter.com/mahadih83660186/status/1907064656851873878?t=VnUB648qAVdQPhBx7sapIA&s=19