7 Factors to Consider When Choosing a Multi-Channel Power Analyzer

Investing in a multi-channel power analyzer is a significant decision for any engineering team, lab, or facility. This instrument is the cornerstone of precision testing, efficiency validation, and troubleshooting for complex electrical systems. With a myriad of models on the market, selecting the right one can be daunting.

Choosing wrong can lead to inaccurate data, safety risks, and frustrated engineers. To ensure you make a confident investment that meets your technical and operational needs, here are the seven key factors you must consider.

Channel Count and Input Type

This is the most fundamental question: how many signals do you need to measure simultaneously?

- Basic Needs: For standard 3-phase system analysis (e.g., motor testing, power quality at a panel), you need a minimum of 4 channels (3 phases + neutral).

- Complex Systems: For testing devices like inverters or converters, you need to measure both AC and DC sides at the same time. This often requires 6 or more channels (e.g., 3x AC output, 2x DC input, 1x auxiliary).

- Input Type: Ensure the analyzer has dedicated inputs for both voltage and current probes (typically BNC or safety-banana jacks) and that it can support the specific type of current sensors you plan to use (e.g., AC/DC current clamps, Rogowski coils, shunt resistors).

Ask yourself: What is the maximum number of voltage and current signals I will need to measure in sync for my most complex application?

Bandwidth and Sampling Rate

If channel count is about the width of your measurement, bandwidth and sampling rate are about its depth and speed.

- Bandwidth: This determines the highest frequency signal the analyzer can accurately measure. For fundamental power frequency (50/60 Hz) and basic harmonics, a lower bandwidth may suffice. For analyzing high-frequency switching noise from VFDs, inverters, or SMPS, you will need a bandwidth of 1 MHz or higher.

- Sampling Rate: A high sampling rate (samples per second) ensures that the waveform is digitized with high fidelity. This is crucial for capturing transient events and precise waveform details. Look for a rate that is at least 10x the required bandwidth.

Ask yourself: Do I need to see high-frequency harmonics and fast transients, or am I primarily focused on fundamental power parameters?

Safety Category (CAT Rating)

This is non-negotiable. Your team's safety depends on it. The CAT (Category) rating defines the level of protection the instrument provides against voltage transients (spikes) in different electrical environments.

- CAT III: For measurements at the distribution level (e.g., distribution panels, busways, fixed loads). This is common for most industrial applications.

- CAT IV: For measurements at the origin of the installation (e.g., utility connection, service entrance, primary overcurrent protection). Required for working at the main breaker panel.

Always choose an analyzer with a CAT rating equal to or higher than the environment you’ll be working in. Using a CAT II instrument on a CAT III circuit is a serious safety hazard.

Ask yourself: What is the highest point in my electrical system where I will be making measurements?

Accuracy Class

Accuracy defines how close the measured value is to the true value. It's typically given as a percentage of reading ± a number of digits.

- Standard Accuracy (e.g., 0.1%): Suitable for most R&D, quality assurance, and efficiency testing applications.

- High Precision (e.g., 0.03% or 0.05%): Required for standards labs, calibration, and certifying energy consumption to strict regulatory standards.

Remember, the accuracy of your entire system is only as good as the least accurate component—this includes your current probes.

Ask yourself: Do my tests require laboratory-grade precision, or is high-standard accuracy sufficient?

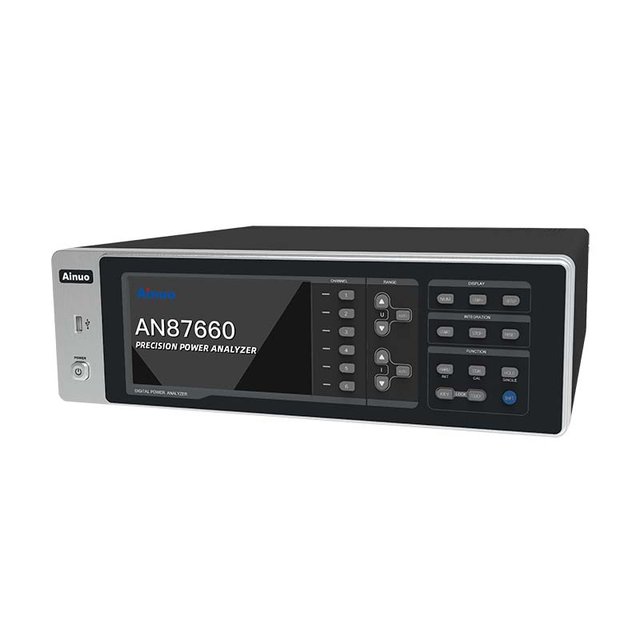

Ainuo high precision power analyzer AN97660(F) is with a basic accuracy of 0.05% of reading + 0.05% of range, which is perfect for motor drives, inverters, and renewable energy systems.

Software and Data Analysis Capabilities

The raw data from the analyzer is useless without the software to make sense of it. The PC software is where you will spend most of your time visualizing, analyzing, and reporting.

- User Interface: Is it intuitive and easy to navigate?

- Real-Time Display: Can you see trends, waveforms, and harmonics live?

- Data Logging: How much data can it store, and at what sample intervals?

- Report Generation: Can it automatically generate customizable PDF or Excel reports with graphs and key data? This is a huge time-saver.

- API or Remote Control: Can you integrate the analyzer into automated test benches using LabVIEW, Python, or other languages?

Ask yourself: How will I extract, analyze, and present the data I collect?

Portability and Form Factor

Where and how will the analyzer be used?

- Benchtop Models: Ideal for lab environments. They often offer the highest channel counts, best displays, and maximum functionality.

- Portable / Handheld Models: Designed for field service, on-site troubleshooting, and audits. They prioritize battery operation, ruggedness, and light weight.

- Rack-Mount Models: Built for integration into automated test systems and production line testing racks.

Ask yourself: Will this instrument live on a lab bench, travel in a service van, or be integrated into a test rack?

Current Sensor Compatibility and Flexibility

The power analyzer itself doesn't measure current; it measures the output of a current sensor. Your choice of sensor is critical.

- AC/DC Current Clamps: The most common type. Ensure the analyzer has the right input types and power (bias) for the sensors you need.

- Rogowski Coils: Excellent for measuring complex waveforms in tight spaces but typically require an external integrator.

- Shunt Resistors: Offer high accuracy but break the circuit to install, which isn't always practical.

- Flexibility: The best analyzers offer auto-recognition of compatible probes, automatically scaling measurements and applying phase compensation.

Ask yourself: What type of current measurements will I be making (AC, DC, or both), and what sensor form factors fit my applications?

Making the Smart Choice

There is no one-size-fits-all solution. The best multi-channel power analyzer for your needs is the one that balances these seven factors against your specific applications, budget, and operational environment.

By carefully evaluating each of these areas, you can move beyond the specifications sheet and select an instrument that will become a reliable, accurate, and safe partner in your engineering projects for years to come.

Ready to see them in action? The best way to evaluate is often a hands-on demo using your own specific devices and test setups.