I'am @mdpolasmia

From #bangladesh🇧🇩

Hi Steemian Friend,

How are you all? I hope you are all well. I am also very well by the grace of Allah. Today I will show you the location of The Rani Concast Steel Mills Limited by pinning. I have been working in that factory for almost six years. I have a lot of love for that factory. Today I will show you the location of that factory by pinning it in Steem Atlas.

Main Gate of Factory

I will first discuss about the 33KV VCB in our factory. This is the main one in an industrial factory. The job of VCB is to control the electricity coming from the power house and supply it to the factory. The electricity is supplied from VCB and goes to the transformer.

VCB Panel

Now I will discuss about the transformer. After VCB, the contribution of the transformer. The furnace used in the steel mills factory is run through this transformer. That furnace can be of any capacity. It can be 10 tons, it can be 15, it can be 20, it can be 25 tons, it can be 30 tons. Our factory uses a 20-ton furnace. That means it is possible to melt 20 tons of slag in the furnace at a time. It does not work only through a transformer, but some other devices are needed here later. I will discuss that below.

Electrical Transformer

Now let's come to the next step. Now I will discuss the panel of a 20-ton furnace. The line coming from the transformer enters the panel directly. From there, it goes directly to the furnace through many different devices. This panel contains capacitors, thyristors, diodes, PLC, busbars, various sensors, water lines, cooling fans, various types of cards, etc. A panel is made with all these. AC is used to keep this panel running. So that it does not get damaged due to heat. Because this panel runs for 24 hours.

20-ton furnace panel

We have to use a monitor to run this panel and the furnace. This monitor signals all kinds of problems. If the water temperature in the furnace increases, then the water temperature will trip and the furnace will not be able to run anymore. The water temperature has to be controlled and restarted. Then the furnace will run again. If there is a problem with any part in the panel, it will be seen on that monitor. The parts can be fixed and restarted by working accordingly. Our 20-ton furnace runs at a load of 6000. Many times the load has to be reduced and increased, then the power can be increased or decreased with the help of the power pot/potentiometer on the monitor. And the load it is running at is shown on the monitor. We call this monitor the melting panel. This monitor runs through the Windows operating system. Which can be controlled from anywhere in the world.

Melting Panel

Now I will discuss about Spectro machine. We have a machine to check the metal in our mill. When the metal is ready, some metal is taken from the furnace and sent to the lab. The people there process it and check it through that machine.

Spectro machine

Now we will discuss the APC blower panel. When a steel mill factory runs, a lot of smoke is produced which pollutes the environment. For this, these fumes are pulled through a hood and filtered to release pure smoke. We call this a blower. To operate this blower, a panel is needed. There is a drive inside this panel. The smoke is drawn with the help of a motor. The drive is used to gradually increase the speed of that motor. Without this drive, the motor will burn out. Once this motor burns out, the company will lose a lot of money.

APC Blower Panel

Now we will discuss the compressor machine. The function of this machine is to create air. In some places in our factory, air is needed. There, air is given through this compressor. There is a quantity of that air such as: 5 kg, 7 kg, 10 kg. This air is not available from nature, so a compressor machine is used.

Compressor Machine

Now let's talk about oxygen bottles. When our metal is in ccm, our hot metal takes a square shape, which we call billet. To cut these, an oxygen bottle is needed. With this, an LP bottle is adjusted.

Oxygen Bottle

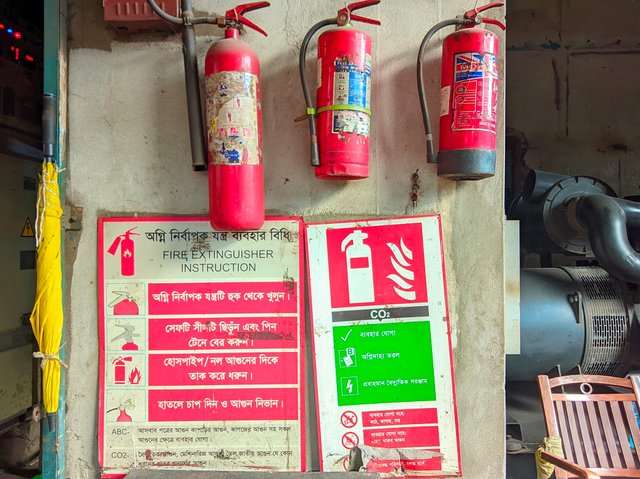

Now let's talk about safety in the factory. Our factory is very strict about safety. Our factory has safety arrangements for all workers. We have fire extinguishers kept at different places. Water lines are installed at many places. So that if there is a fire, it can be easily extinguished.

Fire extinguisher cylinder

Now I will talk about the store room. All the parts are needed in our steel mills factory. All the parts are purchased and stored here. Because if they are not purchased and stored here, they will not be available on time. Production may stop for the parts. There is a store supervisor to look after this store. I am fulfilling that responsibility.

Store room

The panel that I will talk about now is called PLC panel. Our entire CCM is controlled through this panel. There are some motors in CCM that run through the drive in this PLC panel. Then our hydraulics run through this panel. In short, this panel is the lifeblood of CCM.

PLC panel

Now I will discuss about production. Billets are made in our factory. That billet is then sent to another mill of ours and heated in a re-heating furnace. Then rods are made from that billet. To make this billet, first scrap is collected from different places. Then the scap is charged in the furnace with the help of charging crane. Then when the metal is melted, it is sent to CCM.

Scap is being melted in the furnace

Scap is given to the furnace through which we call it a crane. With the help of this crane, the scap is unloaded from the car. And the unloaded scap is given to the furnace. An operator is needed to operate this crane. He alone does these tasks.

Charging crane

When the scap comes from different places, it has to be unloaded with a crane and kept in a specific place. We call it the scap field. From there, the scap is taken and given to the furnace.

Scap storage place

When the metal is ready in the furnace, the furnace foreman informs the CCM people. Then that metal is sent to the ccm. A container is needed to take the metal. We call that container a ladle. The vessel is brought to the front of the furnace with the help of a crane. Then the metal is poured from the furnace and taken to the CCM. After the metal casting in the CCM is completed, the ladle is launched. You will understand by looking at the picture below.

Ladle

What I will talk about now is the mold operator section. Metal casting is done by operating from here. The metal is lowered through the mold tube.

Mold Operator Section

Now I will discuss the tundis operator section. The metal is poured from the ladle into the tundis. From that tundis, the metal falls into the tundis. When the metal is finished, some metal scraps stick to the tundis. The tundis operator cleans them.

Tundis Operator Section

After the metal is cast, it goes to the girder of the CCM. That billet is again kept in a specific place for cooling with the help of a crane. Four people are needed to do this work. That billet cools after a specified time. When it cools down, it is loaded into a car and sent to our rolling mill. To make rods.

Girder and cooling area for lifting billets

Our factory has an electrical substation. From here, the electricity of our mill is controlled. 3 people work here. They look after this substation.

Electrical substation

Now I will discuss about the generator. If there is no electricity in our factory, then this generator is used. It is not possible to run the furnace with this generator. Because it is not that powerful. It is only possible to run CCM with it.

Generator

Some trees are planted in front of our mill. There are some flower trees. There are some fruit trees. These trees have been planted on the initiative of our chairman sir. It looks very beautiful.

Tree garden

Our factory has more than 10 trucks. Rods are delivered to different places through those trucks.

Factory truck

We have a phone from the office. This phone is used to communicate with everyone. This phone is for office use.

Office phone

| Place Type | The Rani Concast Steel Mills Limited. |

|---|

| Location | Shayampur Dhakamatch, Dhaka. |

| Google Map | Click Here |

| Steem Atlas | [//]:# (!steematlas 23.6756875 lat 90.4473125 long The Rani Concast Steel Mills Ltd. d3scr) |

| Owner | Dr. Md. Suman Chowdhury |

| Started | About 20 years ago |

| Number of Employees | About 95 |

| Product Quality | Good |

| Contract Number | 01777758121 |

| Website | Click Here |

| Facebook | Click Here |

| Open | 24 hours |

| Visit Date | 18-09-2025 |

| Score | 10/10 |

| Description Of Photography |

|---|

| Device Name📱 | Location📌 | Captured By📸 |

|---|

| Vivo Y21 | Dhaka, Bangladesh🇧🇩 | @mdpolasmia |

Best Regards:- @mdpolasmia

◦•●◉✿ Thank You ✿◉●•◦

Thank you for posting this on Steem Atlas.

https://steematlas.com/@mdpolasmia/the-rani-concast-steel-mills-limited-dhaka

To help improve your posts on Steem Atlas, and increase your chances of winning in the Atlas Challenge, check out these 21 Tips.

STEEM ATLAS [20 Apr '25] : 21 Tips to Make Better Posts for Steem Atlas

Thank you for setting a beneficiary to @steem-atlas, it will help the project grow.

Dear Sir, thank you very much for supporting me.

This is my Twitter share link:-

https://x.com/mdpolas550189/status/1969212501028954355?t=Vy71TS0qjHEnUb_eq2rQvw&s=19