Thermal Spray Coating Market Size, Share and Trends 2025-2033

Market Overview:

The thermal spray coating market is experiencing rapid growth, driven by expanding industrial applications, demand for surface protection and technological innovations drive growth. According to IMARC Group’s latest research publication, “Thermal Spray Coating Market Size, Share, Trends and Forecast by Product, Technology, Application, and Region, 2025-2033“, The global thermal spray coating market size was valued at USD 10.3 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 16.8 Billion by 2033, exhibiting a CAGR of 6.32% from 2025-2033

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/thermal-spray-coating-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Thermal Spray Coating Industry:

-

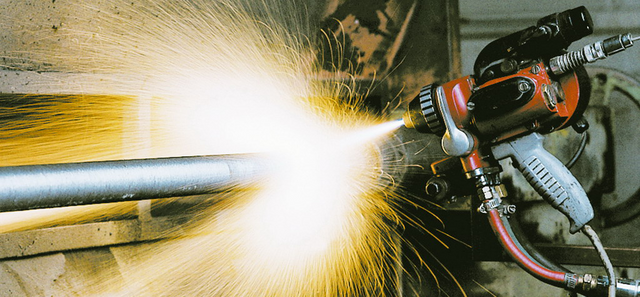

Expanding Industrial Applications

The use of thermal spray coatings is expanding across diverse industrial domains, with growing adoption in railways, oil & gas pipelines, and renewable energy components. These coatings enhance the durability of parts exposed to abrasion, corrosion, or high thermal loads—extending component life and minimizing failure risks. For instance, wind turbine shafts and gas turbines benefit from ceramic or metallic coatings that protect against extreme weather and temperature shifts. Industries are increasingly relying on thermal spray to upgrade aging equipment and improve performance standards without costly replacements, reinforcing the technology's versatility across legacy and next-gen infrastructure.

-

Demand for Surface Protection

As operational efficiency becomes critical in harsh operating environments, demand for advanced surface protection solutions like thermal spray coatings is on the rise. These coatings act as robust shields on valves, pumps, and structural components in sectors like mining, chemical processing, and marine transportation. By significantly reducing exposure to oxidation, erosion, and corrosive agents, thermal spray helps extend service intervals and lowers maintenance costs. With unplanned downtime posing financial risks, more enterprises are investing in surface engineering to safeguard their assets. This emphasis on durability and lifecycle cost savings is boosting adoption across industrial maintenance regimes.

-

Technological Innovations Drive Growth

The thermal spray coating industry is undergoing rapid technological evolution, driven by advancements in material science, process controls, and digital monitoring. Developments in nanostructured coatings offer enhanced hardness and wear resistance, while portable spray systems now allow for in-field applications with high precision. AI-driven diagnostics and sensors integrated into spray booths help operators optimize parameters for better coating consistency. These innovations are not only improving performance but also lowering barriers to entry for small and mid-sized manufacturers. As new application fields like 3D-printed parts and microelectronics emerge, innovative thermal spray solutions are opening doors to high-growth, high-tech market segments.

Key Trends in the Thermal Spray Coating Market:

-

Advancements in Coating Materials and Techniques

Continuous R&D is driving the use of advanced coating materials such as tungsten carbide composites, rare earth oxides, and chromium-free blends. These materials deliver superior performance in applications that demand resistance to erosion, thermal fatigue, and chemical corrosion. Emerging spraying techniques like suspension plasma spray (SPS) and axial plasma spraying offer better deposition rates and microstructural control, enhancing coating adhesion and uniformity. These technological leaps are vital for high-stakes industries like aviation and semiconductor manufacturing, where precision and reliability are non-negotiable. This trend is positioning thermal spray as a critical enabler in next-gen industrial engineering.

-

Emphasis on Sustainable and Eco-Friendly Coatings

Thermal spray technologies are gaining recognition for their environmental advantages, as industries look for alternatives to electroplating and solvent-heavy coatings. Unlike traditional methods, thermal spray systems generate minimal chemical waste and require no hazardous solvents. Manufacturers are now developing low-energy spray processes and recyclable materials to reduce environmental footprints. Coatings that help improve energy efficiency—such as thermal barrier coatings on turbines—also contribute indirectly to sustainability goals. With ESG compliance gaining prominence in procurement and investment decisions, eco-friendly thermal spray solutions are becoming a strategic differentiator in the coatings industry.

-

Integration of Automation and Robotics in Application Processes

Automation is transforming thermal spray operations, enabling precision control, faster throughput, and safer workplaces. Robotic arms programmed with path optimization software can uniformly coat complex geometries, improving consistency and reducing rework. Integrated monitoring systems track real-time variables like spray angle, temperature, and flow rate to ensure quality control. These automated solutions are particularly valuable in industries with high production volumes or strict tolerances, such as aerospace engine parts and automotive drivetrain components. As Industry 4.0 adoption accelerates, the integration of robotics and AI into thermal spray applications is becoming standard for modern manufacturing lines.

Leading Companies Operating in the Global Thermal Spray Coating Industry:

- Air Products and Chemicals Inc.

- American Roller Company LLC

- Durum Verschleißschutz GmbH

- Lincotek Rubbiano S.p.A

- Metallizing Equipment Co. Pvt. Ltd.

- Montreal Carbide Co. Ltd.

- Powder Alloy Corporation

- Praxair Surface Technologies Inc. (Linde plc)

- Progressive Surface Inc.

- Wall Colmonoy Corporation

Thermal Spray Coating Market Report Segmentation:

By Product:

- Metals

- Ceramics

- Intermetallics

- Polymers

- Carbides

- Abradables

- Others

Ceramics exhibit a clear dominance in the market due to their excellent thermal and wear resistance properties.

By Technology:

- Cold

- Flame

- Plasma

- High-Velocity Oxy-Fuel (HVOF)

- Electric Arc

- Others

Plasma accounts for the majority of the market share as it provides precise and high-quality coatings.

By Application:

- Aerospace

- Industrial Gas Turbine

- Automotive

- Medical

- Printing

- Oil and Gas

- Steel

- Pulp and Paper

- Others

Aerospace represents the largest segment on account of the growing reliance on thermal spray coatings to enhance component durability and performance.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America dominates the market, attributed to technological advancements and the increasing demand for thermal spray coatings across various sectors in the region.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302